How Smart Toilets Are Made: JOMOO Smart Toilet Factory.

How Smart Toilets Are made: JOMOO Smart Toilet Factory.

In the other article we have already revealed the secrets behind hardware production, now we would like to tell you about a different product – smart toilets.

Smart toilets have noticeably gained popularity over the last years with people recognizing the added comfort that can be brought to their bathroom experience.

JOMOO has been designing and manufacturing smart toilets for more than a decade. JOMOO smart toilets offer an extensive range of features, such as voice control, sensor activated automatic flush, bidet functions with adjustable temperature and pressure, water filtration and many more.

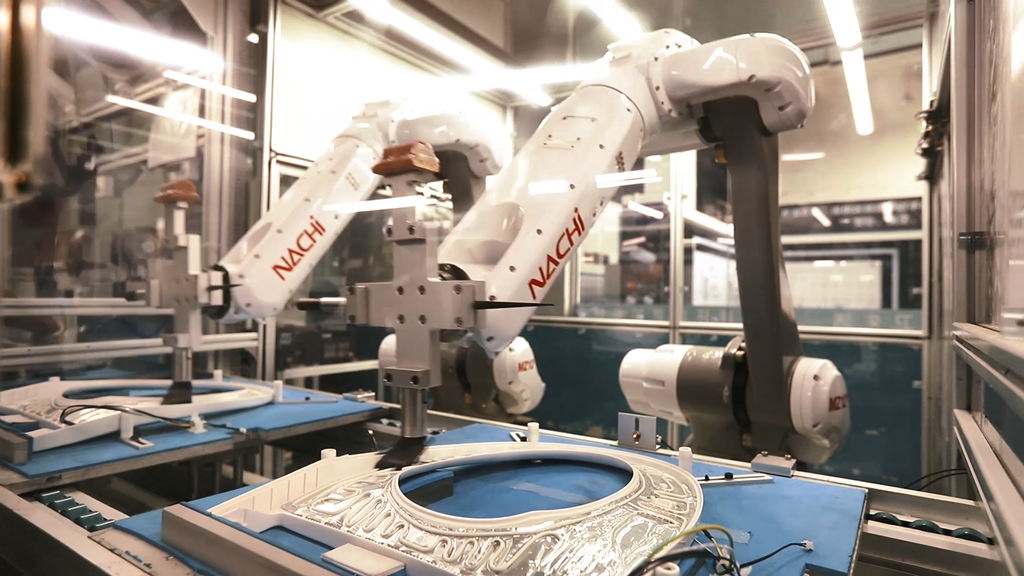

The entire smart toilet factory is run with the use of intelligent manufacturing integrated system. Germany-imported high tech equipment and automation at every step allowed the factory capacity to reach 1 million units annually, with each product going through 200 processes.

The factory is divided into several zones, where different parts and components are manufactured, tested and assembled together. There is a toilet seat production area, bidet function testing line, core components production area, assembly line, packaging line, and a lab.

The production begins with making toilet seats, which are made by precision injection molding. Then sensor and the heating component are placed into the seat to be later sealed in a pressure welding chamber.

The seat heating manufacturing process uses robot intelligence. There are two technologies used here: one is to maintain constant temperature, the other is pressure welding to avoid leakage, with pressure resistance of 200 kg. There are more than 30 processes to go through for the toilet seat alone.

Then ready seats are transported to the testing line, where water is run through the nozzles of every single piece made to test its functioning. The nozzles are made using high precision welding technology and have a silver ion antibacterial coating for users` safety.

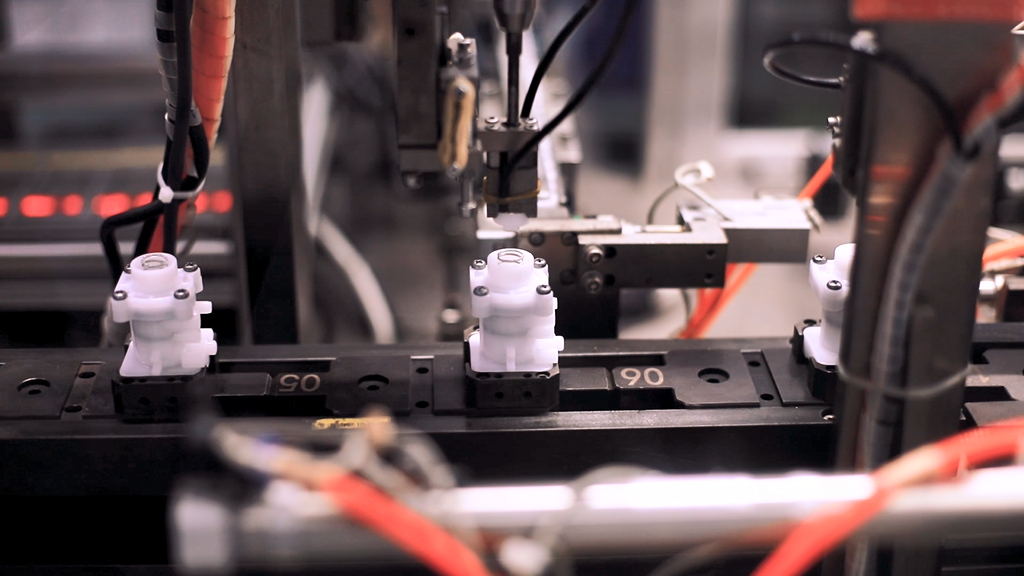

Core components area manufactures parts like pressure regulator valve, ion silver sterilization module, water temperature control unit and other key components.

Pressure regulator valve ensures water pressure stability, while the ion silver sterilization module keeps the bidet nozzles clean, hygienic, and free of corrosion, killing 99.9% of bacteria. The water temperature control unit for the bidet function makes sure that water is heated up instantly. All those components are tested individually and when assembled.

The laboratory tests products` lifecycle and their performance in harsh conditions. All core technologies are thoroughly tested, upgraded and tested again. Products are placed in chambers with extreme temperature conditions, tested to salt spray and hundreds of thousands of cycles to test the life time. The materials are also tested in a designated examination room.

The products are released on the market only after undergoing rigid testing and meeting the requirements.

The ready toilets are then packed and carefully delivered to our stores and your homes.